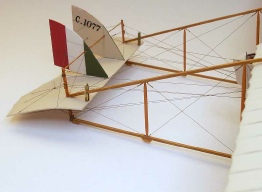

I printed out a set of plans in 1:32 scale then started building the Caudron by making the fuselage framework. I am using 1.0mm x 1.0mm Evergreen styrene strips for the frame. Measurements are taken directly from the plans so accuracy could be questionable. I will now complete the rear section of the fuselage frame then add all the bracing wires. I will be using a 80 hp Le Rhone engine for this model so it will be cowled.

Construction of the fuselage frame is nearly complete. I have been using the 1:32 scale plans I had printed plus I am using information I gained from the net. The larger drawings are very well detailed.

I sprayed the frame with Gunze off white first and when dry I painted oil paint to simulate a wood colour. This time I am using oil paints from MIG Productions, 502 Abteilung set No. ABT 320 Vehicle Weathering and Effects. For my fuselage frame I used the Basic Earth colour. Once dry I will add clear orange to the stringers.

The forward bulkhead was a panel of metal with a series of holes, why, I don’t know. To simulate this I drew the pattern on my computer drawing program to the exact size required, then printed it onto white paper. I then cut it out and glued it to a sheet of plastic card, it is now ready to be fitted to the frame.

I have fitted the bracing wires to the fuselage frame. I used 0.12mm monofilament (fishing line) which is very strong and flexible, CA holds it very well. The small turnbuckles are made from 0.5mm brass tube with o.13mm twisted copper wire for the eyelets, the small connectors are also 0.5mm brass tube but cut to 0.75mm lengths.

The box that the front seat sits on is made from 0.5mm plastic card, it has a slot cut front and back for the control column connecting bar to slide through, the pilot’s rudder bar passes through a slot cut in either side of the box. The observer also has a rudder bar, this is mounted on a small box at the front of the cockpit, both rudder bars will be connected by cables. The seat is made from 0.5mm plastic card, the holes in the seat back are 2.0mm.

The rear covering for the fuselage has been added, this was cut from 0.25mm plastic card and glued in place. I will be fitting rivet decals to this section and then it will be finished in an aluminium colour. The seat and the box it sits on has been painted with oil paints to simulate wood, the oil paint is still wet hence the gloss appearance. The two rudder bars are also painted with oil paints but a slightly darker colour. The observer’s seat will have a padded cushion painted as a leather colour. Next job will be making the pilot seat which is quite large and well padded. The cockpit/fuselage tub is small in comparison to the usual aircraft configuration with a good portion of the crew member bodies exposed to the elements.

I made a base and sides for the pilot’s seat from 0.25mm plastic card, then I used a two part epoxy putty to form the seat. This putty is very good that it retains it shape even when used from first mixing, it stays useable for two hours so this gives plenty of time to play around with the shape of the seat. I want to make the pilot seat a dark brownish colour.

The huge size of the pilots seat can be seen here in comparison to the observers

seat. The observers seat has a thatched cane seat, to simulate this I drew the pattern

on my computer then printed it out, I simply cut it out then glued it to the seat.

The pilot’s seat has been painted with Humbrol No.62 Leather enamel paint and sprayed

with a satin clear. I also made and fitted the connectors to both rudder bars ready

for the control cables to be fitted. The small black linkages mounted to the floor

just behind the perforated bulkhead is for the throttle cables from the throttle

quadrant, quite an unusual set-

I made the two throttle quadrants from 0.25mm plastic card, the throttle levers are made from flattened 0.5mm brass tube, I used CA to glue the lever to the quadrant. Once fitted to the fuselage frame I fixed the control cables connecting each throttle then down to the linkages on the floor of the cockpit, I used 0.12mm monofilament for the cables. The control columns are made from 1.2mm brass tube with very thin plastic tubing slipped onto the top ends to act as the hand grips. The rod connecting the two control columns is made from 0.6mm brass tube and fits into holes I drilled into the two control columns. I also fitted the control cables that connect the two rudder bars, these are made from 0.12 mono. A tacho has been made from 3.0mm brass tube, I used an instrument decal from the Airscale range of instrument decals and slid it into the tube with a clear plastic instrument lens. The tacho is mounted onto a piece of thin brass sheet which is bent to the appropriate shape so it mounts onto the fuselage frame. The flexible tachometer drive is made using two 0.6mm coil springs, these have been joined together using a length of 0.13mm copper wire inserted into the end of each spring, a drop of CA holds it all together. I drilled a 0.7mm hole into the bottom of the tacho and glued the flexible drive into the hole, the drive then passes out through the forward bulkhead.

The two forward bulkheads are made from 0.25mm plastic card and the stringers are made using 1.0mm square styrene strips. I also made a small shelf which protrudes into the observers area, this shelf and the forward upper bulkhead will be timber grained. I applied 0.25mm styrene sheet over the forward upper fuselage section, this area actually holds the fuel tank in the real aircraft, there will be two filler pipes and caps protruding through the top of this section. Once painted, this top forward section will be depicted as wood, directly below will be aluminium and the remainder of the fuselage will be fabric.

The forward section of the fuselage has had the ‘’wood’’ applied using oil paints. I also fitted the engine intake pipe which is made from a length of 1.2mm brass tube. The engine cowl is made from 0.25mm styrene sheet glued into place, I then added 0.5mm square stock around the outer edges of the cowl, once dry this was sanded back to achieve a more rounded shape.

The bottom wing has been formed by using three sheets of 0.5mm styrene sheet. I firstly cut the wing section from the plans then transcribed the shape onto the plastic sheets, these were then cut out using a sharp scalpel blade. The three sheets were glued together using plastic glue making sure the entire surface is covered with glue. The wing is then taped over a length of aluminium pipe to obtain the correct curved shape, after about half an hour the tape is removed and the wing shape checked against the plan, any final adjustments can be made by hand. I allowed the wing overnight to dry and once fully cured the wing is very rigid. I then sanded the trailing and leading edges of the wing to achieve the correct shape, final smooth sanding is still required. This is a very easy way to make wings.

The bottom wing is only very short in comparison to the top wing, and as can be seen in the photos the fuselage tub is also quite small. I will now give the wood on the fuselage a coat of clear.

The forward top section of the fuselage wood has been coated with clear orange and when dry was sprayed with satin clear. Cockpit padding around the front was made using some small plastic tube split then glued onto the top of the forward fuselage. The wing ribs on the front half of the wings were made from 0.5mm x 0.5mm Evergreen strips, the rear half are made from 0.8mm round Evergreen stock. The reason for the larger rear ribs is because the wings operated with wing warping. Once the ribs were glued to the wing I gave the entire wing a good brush coat of Automotive Primer/Putty, I allowed this to dry overnight then sanded it all down giving me the hollows on the wing between the ribs. A bit more final sanding is needed before the final coat of paint is applied.

I used the 80hp Le Rhone engine from a WnW Sopwith Pup kit, the engine assembled very easily and paints up to be a very nice looking engine, it is only loosely fitted here just for photo purposes. The propellers in an Eclair, this was commonly used on the Caudron, this propeller is a laminated wood propeller made by Doug Craner

The fuselage fabric has been painted but the fuselage frame still shows through the fabric, this is a great result and is very much like the real aeroplane. The engine has now been fitted to the airframe, but the bottom wing still needs more work before it can be fitted to the fuselage.

For strength I decided to use 1.5mm solid square brass for the undercarriage/tail booms. I bent the brass by hand to achieve the required shape, it is quite solid and took a bit of effort to bend. I have sat the fuselage on top of the booms to show the position in which they will sit.

I will be using four of Steven Robson brilliant spoked wheels for this build. I have fitte an axle made from 0.9mm brass tube, I fitted four small brass washers over the axles with a small length of spring between each set of washers. The blank space in the centre is where the axle will sit on the boom and lashed on with bungee cord, the two steady arms will bolt to the boom.

The support frames for the booms are made from 1.0mm brass tube. I drilled 0.7mm holes into the square brass then inserted short lengths of 0.65mm copper wire into the brass tube, this then fitted into the holes drilled into the square and was held together with CA, this makes a very strong joint. The wheel set is sitting under the boom just for photo purposes. It will eventually sit on top of the boom.

These two photos show the fuselage sitting in position on the undercarriage frame which also doubles as the tail boom. Once all the bracing bars and rigging is attached to the undercarriage it will be a very strong assembly. I will be using the same 1.5mm solid square brass for the top tail booms as well.

The undercarriage is now fitted to the bottom wing, the front cross brace adds an enormous amount of strength to the assembly. There will be a lot of rigging added to the fuselage which connects to the wings and fuselage, this will also add strength to the assembly. The spoked wheels from Steven Robson are absolutely brilliant and very strong, they enhance the model beautifully.

To keep both tail booms/undercarriage straight and aligned I glued a length of 1.0mm brass tube to the bottom of each boom, I used CA to glue this tube. This is important to do BEFORE rigging commences, if this is not done the rigging will pull the booms out of alignment. CA does not have a very high sheer strength so once the rigging was completed it was a simple matter to twist the tube off using a pair of pliers.

The undercarriage rigging is now completed. I used 0.12mm monofilament and 0.5mm brass tube for the little sleeves, CA holds it all together very well. I did not apply very much tension to the rigging which runs out to the wing tips, I didn’t want to pull the wing down as it is supposed to be straight. There is quite a bit of rigging under the aircraft but most of it is unseen with the model on its wheels. The last photo with the figure gives a good size comparison. The spoke wheels I have used are a fraction too large in scale for this particular model but the size difference is hardly noticeable. The wheels and undercarriage supports have been paint with Gunze H337 Greyish Blue FS35237 US Navy.

I made the wing struts from standard wood toothpicks, the toothpicks I used are the round type, I also used a No.11 scalpel blade. I firstly cut one end of the toothpick to form the top of the strut, I then scrapped the length of the toothpick on both sides with the scalpel blade, it took about 30 scrapes each side to reduce the size of the toothpick to 1.0mm in thickness. Once this size was achieved I rounded the edges slightly with a smooth sanding stick. I measured the strut against my plan and cut it to length, then I tapered the bottom end again using the sanding stick. I cut a short length of 2.0mm brass tube and fitted it over the tapered end of the strut. This was then flattened with a pair of smooth jaw flat pliers. A short length of the strut is exposed beyond the brass tube to fit inside the hole drilled in the bottom wing to locate the strut. I then painted all the struts with oil paint to simulate a wood look, the struts where then placed in my heat box and allowed to dry over night. Two of the struts need to have special treatment, these two struts, one on each wing, take the control cables from the cockpit. I needed to make four pulleys which were made from small brass washers, a length of 0.3mm brass tube acts as the axle. I made the plate to fit the bottom of the strut from 0.25mm plastic card glued directly onto the struts, a hole was drilled either side and the pulleys attached using super glue. Holes were drilled into the plates to correspond with photos of the original machine. The special plates and pulleys as well as all the other brass tubes on the other struts will be painted, colour to be determined.. Making the struts from toothpicks will give me the strength and rigidity I am after to support the top wing. All the struts have been sprayed with a coat of Humbrol clear which is a 50/50 mix of satin and matt.

The struts were glued to the wing using five minute epoxy, this resulted in a very strong bond. I also made and fitted all the turnbuckles to the bottom wing. These are made from 0.5mm brass tube with an eyelet made from twisted 0.13mm copper wire, these are one ended turnbuckles as they are mounted directly into the wing. I drilled a 0.4mm hole into the wing to accommodate the turnbuckles, CA holds them very well. My next task is ti make the top wing, it will be quite a bit longer than the bottom wing and will have to be done in sections, I will use the same method as I used to make the bottom wing.

The top wing is made up of two layers of 1.0mm styrene sheet glued together, this was made in a very similar fashion to the bottom wing. I have glued all the ribs on the top side of the wing and given one spray with filler, it will need quite a few coats of filler then sanded down to form the hollows between the ribs. As can be seen by the photos the top wing dwarfs the bottom wing, it is over 41cm in length. It sits on the struts very nicely as shown in the last photo. I will now spend a lot of time preparing the wing, once the top is completed I will add all the ribs to the bottom of the wing, lots of sanding to do. I have also sanded out the scallops along the trailing edge of the wing, this was done by wrapping some sand paper around a piece of dowel.

The top wing is just about done, just needs a coat of satin clear. I have just positioned the top wing into the struts for photo purposes, it is not glued at this stage, as you can see it is quite a long wing when compared to the rest of the model. The spoked wheels and the laminated wood propeller stand out well in some of these photos, the wheels are from Steven Robson and the wood propeller is from Doug Craner, both excellent products. I will now fit the eyelets to the bottom surface of the top wing.

Mounting the top wing was quite simple, I placed the inverted wing on my work bench,

the wing has no dihedral so a good flat surface was excellent. I inverted the model

and placed it onto the wing making sure the struts lined up with the holes pre-

I am using 0.12mm monofilament for the rigging, this will add a lot of structural strength to the wing assembly just like the rigging on a real aircraft. This aircraft has double flying and double landing wires so rigging will take some extra time.

Here is a size comparison photo. The other model is a WnW Sopwith Snipe (late) and as can be seen the Caudron is not a larger aeroplane considering it is a two seater. The top wing of the Caudron makes it appear larger.

One side of the rigging is almost completed, as can be seen there is quite a bit of rigging due to the double flying and landing wires. All rigging wires after they are installed are painted with Mr Metal Color Stainless, the wings are protected with paper to prevent the stainless paint flicking onto the surface.

The rigging is now finished on this side of the wing. I have also added the outrigger struts which are 75.0mm long. They were made from bamboo skewers and shaped with a No.11 scalpel blade after they were turned down to 2.0mm in my lathe. I will add the oil paint colour to the struts in situ.

Work has begun on the left side of the wing rigging, the rigging is tensioned in such a way that it keeps the wings level, so some wires need quite a bit of tension. The rigging has taken quite a bit of time but I do enjoy doing it. This photo gives a good representation of the unusual appearance of this aircraft, the very small lower wing certainly looks out of place.

The wing rigging is now finished. I also added the outrigger struts, the are made from bamboo skewers which have been turned down to 2.0mm on my lathe, I then shaped them using a No.11 scalpel blade then cut them to length. I made a hinge where they mount onto the bottom wing, this was done using one eyelet on the wing and two eyelets in the end of the strut, a short length of 0.3mm brass tube is used for the hinge pin. The top of the strut is tapered and fits into an elongated hole in the bottom of the top wing, it is all held in place with CA. The small interconnecting struts are made from bamboo toothpicks. I used oil paints directly onto the bamboo to add colour, no base coat was needed. The double rigging wires did cause one issue, one set became a little slack so I used a soldering iron to heat the lines, this regained the tension on the two lines. If you are using a soldering iron to tighten monofilament be careful not to touch the line with the iron, it will instantly break. Place the hot iron til close to the line you wish to tension and move the iron along the length of the line, do not hold it in one place for too long, you will see the line tension once heat is applied, as soon as you have regained tension remove the soldering iron. The bamboo struts, monofilament rigging and bamboo outriggers have made this a very strong wing assembly.

The tail plane is made from two pieces of 0.5mm styrene sheet cut to shape then glued together with plastic glue. The shape was formed by taping the wing around an aerosol can, the rear of the wing was kept up from the can. The rib tapes are from 0.75mm masking tape applied directly to the surface, the paint seals the edges and makes for a good seal, a few coats of clear will also lock the tapes down.

The twin fins/rudders are cut from 1.0mm styrene sheet, the trailing edge of the rudder was sanded down to a feathered edge. The rib tapes are again 0.75mm masking tape whish sticks very well to the clean styrene sheet. The two rudders are shown here with the inside surfece painted, the outer surfaces will be painted green, white, red. The two inside surfaces will carry the serial number.

NOTE

I made a mistake with the wing rigging, the outer struts should not have the stagger wires fitted. As this aeroplane has wing warping the outer section of the wing needs to be flexible, the strut will move up and down as the wing is warped. A cable is connected to the bottom and top of the outer rear strut which is the warping cable. The modifications are very easy to perform and will not effect the rest of the rigging. I searched the net and found the following diagram, this will help enormously with the wing warp rigging and tail warp rigging.

The tail plane is well under way, the twin fin/rudder assemblies are now fully painted and have has the decals applied, they have also been clear coated with flat clear. The top tail booms are made from 1.6mm square solid brass, a slight bend was needed where it fits over the curve of the wing. The two uprights which hold the tail plane are made from bamboo tooth picks worked down to the correct shape and size. The cross bar which passes through both fins is a length of 0.7mm brass tube, this will be coloured to look like wood. The whole tail assembly seen here is only sitting for photo purposes, nothing is in it’s correct position so things may look a little out of whack, but it gives a general feel of what it is going to look like when completed.

These three photos give a better idea of how the tail plane will look when final assembly takes place. You can see how the fin sits neat onto the horizontal stabiliser, of course there will be plenty of rigging wires to strengthen the whole tail assembly plus the warping cables for the “elevator”. I have also drilled all the holes in the top booms for the eyelets, these will be used for the tail boom rigging.

The top boom and tail are now fixed in position, even without rigging the tail assembly is quite strong. I used toothpicks again to complete the tail boom uprights. All the “wood” bits have now been coated with oil paints. Once the oil paint dries all I have left to do is the tail and tail boom rigging, there will be quite a bit of rigging around the tail as it is of the warping kind.

THE COMPLETED MODEL

The control cable for the warping elevators are double wires which come from the fuselage and pass through Bowden outer cables attached to the warping mast by wooden blocks, the rudder cable is mounted in the same way but is only a single cable. The elevator cables are joined and then split into four to act as the warping cables for the elevator, the same applies under the tail plane. Below are a series of photos showing the cable arrangement and also the bracing wires for the fin and tail plane, the rudder cables are also shown quite clearly in the photos.

This scratch build has been a lot of fun and I must say a big thank you to Steven Robson (Spoked Wheel Shop) for supplying the four immaculate spoked wheels and to Doug Craner for supplying the amazing hand made laminated wood propeller.

Index

Index